Yuken Hydraulic Pump Repair

00 INR

Product Details:

X

Yuken Hydraulic Pump Repair Price And Quantity

- 1 Piece

- 00 INR

Yuken Hydraulic Pump Repair Trade Information

- 1 Piece Per Day

- 1 Days

Product Description

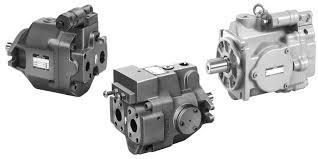

Yuken Hydraulic Pump is used in a wide range of applications, including in industrial machinery, construction equipment, agricultural machinery, and other heavy equipment. This is an efficient, reliable, and durable pump that is often used in demanding applications where performance and reliability are critical. Repairing a Yuken hydraulic pump involves disassembly, inspection, cleaning, reassembly, testing and final inspection. A specialized team with knowledge and proper tools carries out Yuken hydraulic pump repair while following proper safety protocols.

Precision Spare Parts and Materials

We utilize only high-grade steel and specially selected alloys for all components replaced during the repair process. This ensures lasting reliability and the ability to safely withstand pressures up to 315 Bar after refurbishment, closely matching original manufacturer standards.

Efficient Turnaround and Thorough Testing

Our team typically completes repairs within 3 to 5 working days. Every serviced pump is thoroughly tested on a hydraulic test bench, up to its rated capacity, confirming restored functionality and performance before returning it to your operation.

Flexible Onsite and Offsite Services

We offer both onsite and offsite repair solutions throughout India, adapting to your operational needs. Whether your facility requires repair on location or at our specialized workshop, we ensure seamless logistics and support.

FAQs of Yuken Hydraulic Pump Repair:

Q: How is the repair process for Yuken hydraulic pumps carried out?

A: The repair process begins with a detailed inspection, followed by the replacement of worn components using high-grade steel and alloys. The pump is then reassembled, tested on a hydraulic test bench, and delivered back to the customer with restored performance.Q: What types of Yuken hydraulic pumps can be serviced?

A: We support piston, vane, and gear-type Yuken hydraulic pumps used in various industrial applications. Our expertise covers a wide range of models and capacities.Q: What materials are used for spare parts in the repair?

A: Only high-grade steel and advanced alloys are used for all spare parts, ensuring compatibility, durability, and reliable operation under high pressure conditions.Q: How long does the repair service typically take?

A: Most repairs are completed within 3 to 5 working days, depending on the pump type and the extent of refurbishment required.Q: Where are the repair services provided?

A: Our repair services are available both onsite at your facility and offsite at our specialized workshops across India, ensuring flexibility and convenience.Q: Is there a warranty on repaired pumps?

A: Yes, all repaired Yuken hydraulic pumps come with a conditional warranty ranging from 3 to 6 months, offering you added peace of mind.Q: What are the benefits of choosing this hydraulic pump repair service?

A: You benefit from restored pump efficiency, extended equipment lifespan, reduced downtime, and cost savings over new pump replacement, thanks to quality materials and comprehensive testing.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Hydraulic Pump Motor Repairing Services' category

Back to top

Call Me Free

Call Me Free